GURUS Cloud Connect Ep. 12

Supply Chain & Demand Planning Trends in Food and Beverage for 2021 |

January 2021

Episode Topics:

| | What is Blue Ridge Software for Supply Chain and Demand Planning? |

| | What is the Cause of the Bullwhip Effect in Supply Chain? |

| | How Are Buyer Trends Expected to Transform in 2021? |

| | What is the Difference Between Supply Chain Planning and Sales and Operations Planning? |

| | What has been the impact of price on demand? And Vice Versa? |

| | What is forward buying and how does it work? |

| | How Does Blue Ridge Demand Planning Work with NetSuite ERP |

| | What are the Core Signs for Manufacturing and Distribution Businesses That Need to Upgrade Their Systems? |

| | How is Seasonal Item Inventory Being Impacted by the Pandemic? |

| | Emerging Trends in Buyer Behavior and Supply Chain Forecasting for 2021 & Possibly 2022 |

| | Do You Need to Implement ERP First to Adopt A Demand Planning Solution? |

Talk to a NetSuite Professional About Demand Planning for Your ERP

Episode Overview:

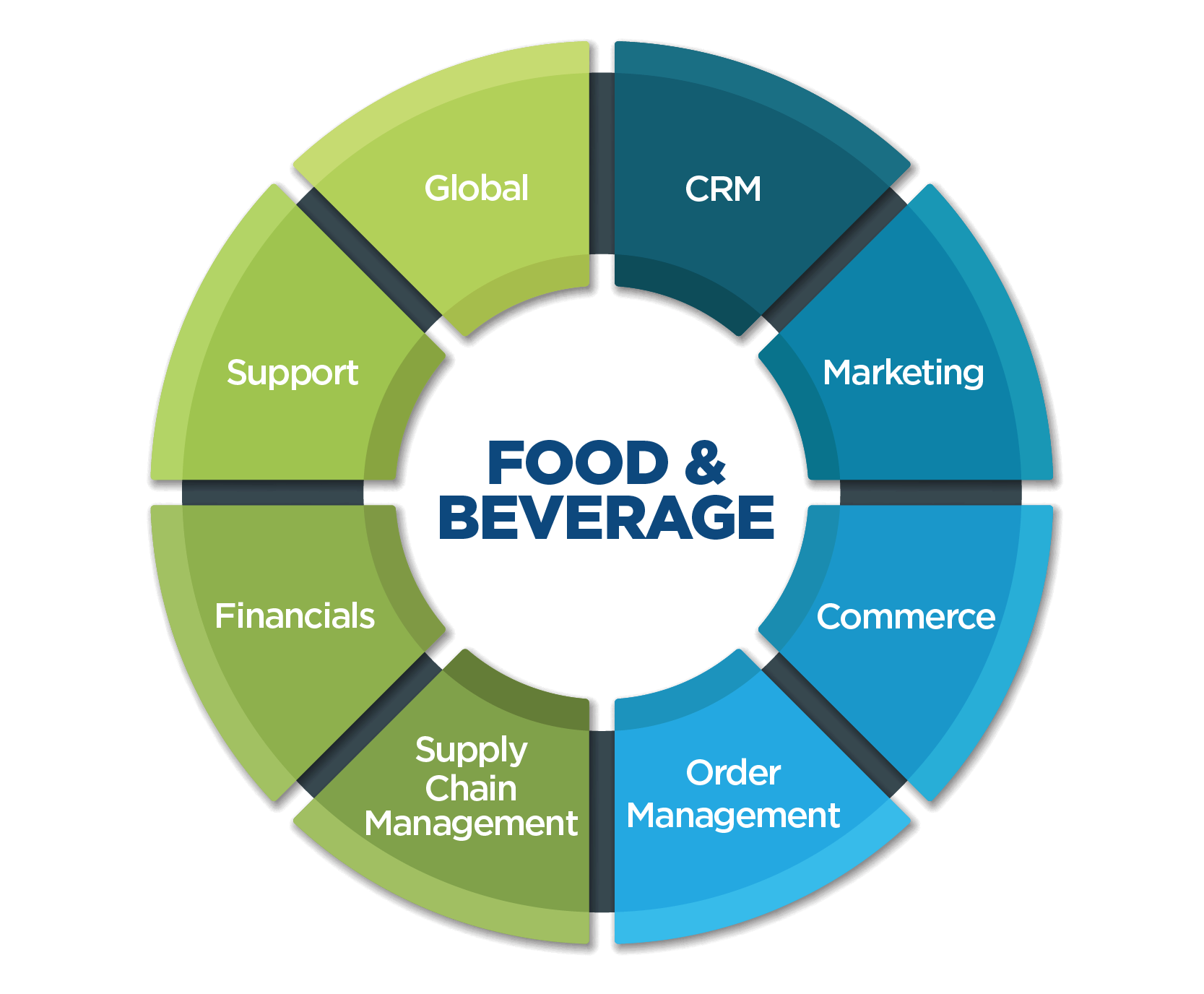

The Food and Beverage industry has been at the forefront of 2020’s economic impact, forcing a wave of concerns around supply chain and demand planning. Going into 2021, there are sweeping changes across the industry as manufacturers and distributors in all industries seek to get ahead of new trends and ensure they can meet growing buyer demands.

In this latest episode of GURUS Cloud Connect, we’re joined by Blue Ridge, the industry leader in cloud-based supply chain solutions. We address emerging trends around demand forecasting, seasonal item inventory and demand planning for Manufacturers and Distributors across all industries and especially in the Food and Beverage space. For our viewers that are NetSuite Users, we also discuss the benefits of Blue Ridge Demand Planning for NetSuite, its features and how the two systems work together.

Our guest for this segment is:

Sven Aunapu, Senior Director of Business Consulting at Blue Ridge, the industry leader in cloud-native supply chain solutions.

Major Distributors and retailers across North America use Blue Ridge software to proactively measure the impact of every purchasing decision before they make it. Businesses have gained more certainty, speed and assurance to their value chain by leveraging their demand planning solution.

Episode Takeaways (Q&A with Sven Aunapu):

Can you talk a little bit about Blue Ridge and the kind of clients that you usually work with?

Blue Ridge has been in existence for about 15 years now and we have primarily focused on the wholesale distribution side of the business. We have since gone ahead and moved into the Retail market as well. The verticals that we're dealing with are really across the board - food service, food wholesale, food and beverage, wine and spirits - it's really across the gamut. If a business has inventory and they buy inventory, then we're the solution they consider along the line of their growth journey.

When do people reach out to you and what are they asking for?

In some cases, they’re looking to streamline and in other cases they're looking to really impact their service, and in others they're looking to reduce inventories. When we're talking about the food and beverage industry, I think there's been a massive shift in the conversation around supply chain.

Without beating around the bush, with covid obviously in 2020, a lot of things have changed for food and beverage as

a whole - especially in wholesale distribution heading into 2021. Most, if not all, companies were caught by surprise and had to react very quickly and adapt... and they don't want that kind of a sudden shock impact to their processes to happen again.

Many of these businesses want to, when there is a return to normalcy, be able to go again and obviously focus on those items that they were replenishing and that they were selling on a regular basis. However, they now have a whole new ( in some cases) business line that they need to go ahead and manage, and they need to be more proactive. They need to think about...I hate to say it but, the next “pandemic”-level occurance of unpredictability that could happen. It might not mean a pandemic but the next disrupter that's going to happen - how do they handle it?

One of the terms that we heard floating around a lot in supply chain in 2020 was “the bullwhip effect”. What is the cause of the bullwhip effect in supply chain?

What is the bullwhip effect?

Think of it as a ripple in a lake. When you drop a drop of water, and you can see it spread out in waves and that's what's happening with the bullwhip effect.

For example, with covid, we had some items where the demand just went right through the roof. Well, with demand going up through the roof, you're going to have changes in demand variability, which in turn affect how much safety stock you're carrying.

Then, how much safety stock you're carrying affects your capacity at the DC level so all of this is really a migration from what seems to be a small change and actually ripples up and becomes a big change.

Based on what you're saying we're seeing buyer trends transform. Going into 2020, I don’t think we could have predicted the popularity of basic household items like toilet paper and hand sanitizer...or even certain groceries, deliveries, fitness equipment, and the list goes on.

Now, going into 2021 how do you think shifting buyer trends are going to transform the industry and impact demand planning in general?

Before there was a pandemic, most people never really thought about stockpiling toilet paper, right? It was only when we became worried that it wasn't going to be available that we ran out and we bought every single piece of toilet paper we could find, whether it was good or not. As we get back into the normalcy of pre-Covid, we're going to see people going out and really buying the things that are going to be making them feel good again.

But then there is a whole other side to it, another analysis they need to do to figure out how they get back into the right inventory. How do you get the right stock into position on items that sold well once and maybe aren’t your high performers right now so you haven’t been replenishing them as much? There needs to be an agility to businesses in the upcoming years, a preparedness. They’ve got to be able to make impactful decisions and they have to be able to make them quickly.

Can you talk to us a little bit about the difference between supply chain planning and sales and operations planning?

It's heavy lifting versus fine-tuning, that's really what we're talking about with the actual demand planning. What you're looking at is the minutia, meaning the item level and location level metrics. How is the item forecasted? What does the demand look like? What is the safety stock involved with it? What is the lead time between the manufacturer and the distribution center? These are all the heavy lifting pieces that need to be managed by a demand planning solution.

When we look at sales and operations planning, what you're talking about is fine tuning at a higher level. It's about category management, it's about channel management - so you want to take all the information that you have that's at that item level and you aggregate it up so that you can plan better.

What is the impact of price on demand? Doesn’t price drive demand and demand drive price?

There are a lot of components that really fit in with that price demand picture. For example, there are definitely categories that you don't want to make adjustments to and overstocks you do. You want to reduce the price on those, but for inventory where you've got critical inventory leads but not a lot of inventory, you don't want to reduce the price on those.

When we're going in and we're really analyzing price, we've got to look at a number of components like inventory level and the channel that you're selling into.

E-Commerce is excruciatingly sensitive to price changes so that's something we've got to look at and time of the year. You're going to pay more for ice cream in the summer than you're going to be paying for it in the winter.

What is forward buying and how does it work?

There are two different types of forward buying.

The first type is when you're really preparing for an event so you've got to have product available. If you're opening up a new distribution center, you've got to go ahead and preload that distribution center with inventory before the demand actually occurs.

Within blue ridge, when we're talking about forward buying, we're talking about a different type of pre-loading of inventory and that would be an investment buy.

If there's a price increase or if there's a price decrease, one of the things that you also need to take into consideration would be the tariffs. That would be a type of forward buying where you're really looking to bring in more inventory, but rather than preparing for an event, the purpose is to go ahead and increase your inner margin.

What should a food and beverage manufacturer or distributor in 2021 look for in terms of a supply chain or demand planning solution?

I think you've got to look at a solution that's going to be able to address a number of issues. Perishability is one of those issues and when we're talking about perishability, it's a lot more than shelf life you need to be looking at.

How do you handle ordering products multiple times in a week? Because when you do that, you've got multiple or dynamic order cycles, which means you've got varying lead times within the week.

All of that needs to be considered and for a food and beverage organization that's critical seasonality, which is obviously something that's very important.

Seasonality is something easy to look at and discuss, but the difficulty inherent is when you want to apply seasonal profiles. That's probably one of the trickiest things in the business and you need to be really careful. A good seasonal profile is wonderful but a bad profile could be the kiss of death. You have to make sure that when you apply a seasonal profile, you apply them correctly.

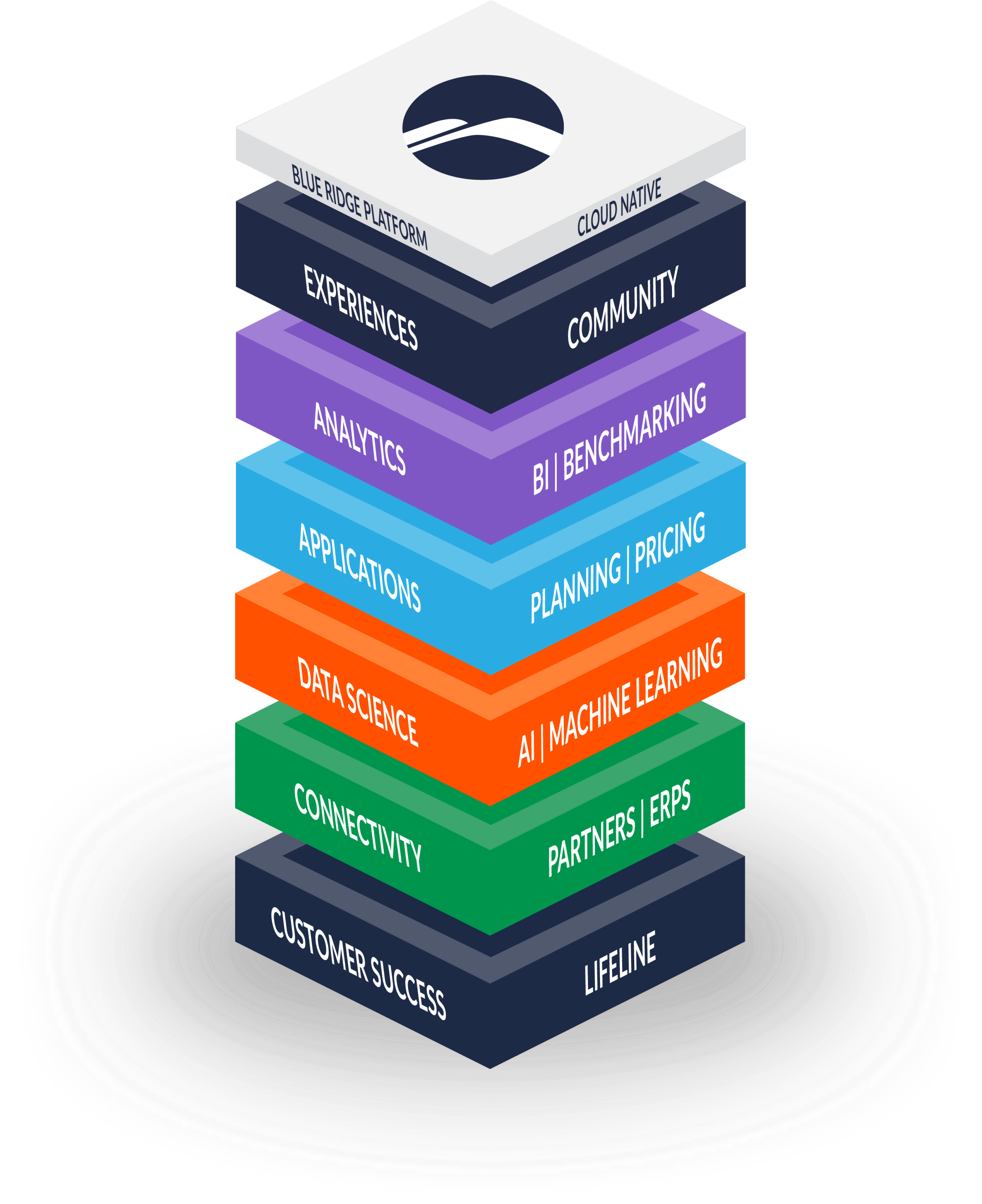

What is Blue Ridge’s Solution for Demand Planning? And How Does Blue Ridge Work with NetSuite ERP Software?

Blue Ridge Demand Planning for NetSuite is an all-encompassing solution that provides the NetSuite customer with the ability to go ahead and plan for and bring in that forward buy inventory.

Whether it is events or it is for a discount opportunity, it is the solution that will do the forecasting, the calculation of safety stocks, forecast the lead time for you and build the orders.

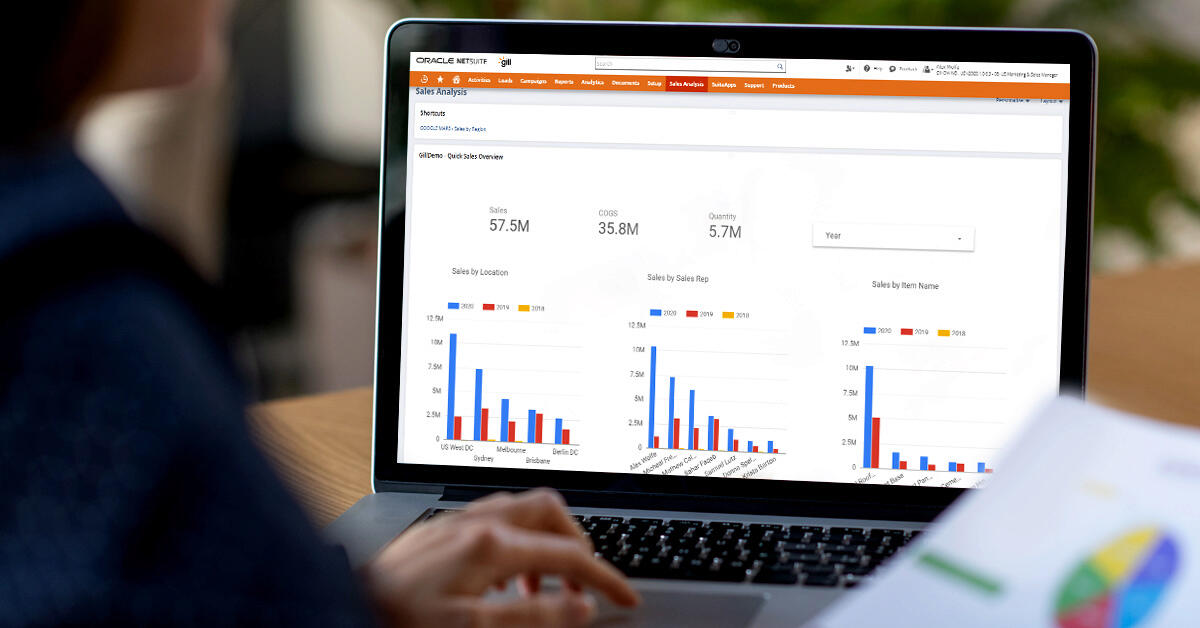

The relationship that Blue Ridge has with NetSuite is a wonderful one from the consumer perspective because the work that has been done in the NetSuite suitelets has been phenomenal. It's given our customers the ability to go ahead and implement significantly quicker than we could with any other Enterprise Resource Planning system.

NetSuite customers that use Blue Ridge for their Supply Chain and Demand Planning will describe the relationship in terms of Blue Ridge being the crystal ball. While NetSuite gives its users visibility across their business, Blue Ridge software helps them “predict the future”. It lets the business know when and where to allocate resources.

NetSuite provides Blue Ridge with the source master and the item master. With all of that information provided, Blue Ridge does the heavy lifting of giving those orders back to NetSuite.

What are the core signs for Manufacturing and Distribution businesses in the Food and Beverage industry that they need to upgrade their systems?

Companies today are much more proactive and they have to be that way because of the competition. Competition is greater than it's ever been before, everybody wants to have the best and they want to be the best.

Businesses in the food industry want to be #1 for one of two reasons:

- They want to own the market

- Or they're preparing themselves to be sold

Those reasons are the driving factor behind the systems they choose. Whether they want to be the most competitive and drive the market or they want to be eventually bought out by a market leader, they need to streamline their processes and not only survive in a fast-paced environment but thrive from it.

How does Blue Ridge software complement NetSuite’s ERP system? What are the gaps that it fills?

With the Blue Ridge solution, that forecast is used to go ahead and build orders, to understand how much inventory is actually required for the lead times associated with that item and that source. What is the item level? The safety stock forecast is used for that order cycle. We've got to understand what is the demand going to be during the time that the order cycle is is going on, so it's all of those components and then being able to go ahead and look at MOQs and events and forward buys, and building up to an order that is a right size profit oriented service level driven order. That's the magic.

Is it becoming more difficult in 2021 to predict buyer trends? How will it impact seasonal item inventories?

One of the things that a lot of the food service organizations and food and beverage organizations do is that they typically like to forecast within a larger window. They look at what is typically a four-week or monthly window. They like the forecast as soon as they notice that there is a trend occurring and the system measures that trend.

Then, they have the opportunity to go ahead and change that forecasting cadence to be quicker so the system responds quicker and they find themselves getting in much better shape from a forecast accuracy perspective.

So, my answer is that I don't think it's getting harder - I think it's getting easier. Even with some of the advanced seasonal capabilities that are out there, it's requiring maybe a different kind of buyer today, one that's more analytic. But if you have a buyer that is analytic, who's asking the questions, the tools are out there to make their job very easy.

We have a customer that, within the first week of covid hitting their business - and they were in a different kind of business where the demand actually shot right through the roof - they were able to respond very quickly within that first week to the demand changes. They made the inquiries and they were able to go ahead and make some adjustments that allowed their organization to maintain a forecast accuracy of about 98 percent during what for many was a highly unpredictable period.

Then, we've got other organizations, specifically within food service, where there wasn't huge demand in the beginning. Other than for specific categories, it was just like the bottom of the floor had dropped out and again they needed to be able to react very quickly.

I think that's impacting growth strategies for manufacturing companies in the food and beverage space. They must be thinking differently about things now. When we say they're thinking of things differently, it's kind of like in fashion. You know how they say fashion always repeats itself? Well, what we're seeing now is that what's old is new again and what I've been seeing is a much more collaborative environment between food and beverage and the manufacturers.

Food and beverage distributors are able to provide really accurate buy projections, sell projections and inventory projections that the manufacturers can go ahead and use to take advantage of in their production planning. Those manufacturers that are taking advantage are able to supply products much better, first of all. Second of all, they're starting to take on the mind frame of the distributor, of the wholesaler, so we’re seeing a growing sharing of information and a transformation of the way the organizations are thinking. It’s like they're almost becoming one now.

What will buyer trends be like post-vaccine? Where does data become crucial when considering the future of not just Food and Beverage, but Manufacturing and Wholesale Distribution, Retail, eCommerce and more?

What businesses have to be able to do post-covid and post-pandemic is to go back and look to see what the demand patterns were prior to the pandemic. Those are the levels that we need to get back to and the data is out there. Your ERP solution will have that data, but it’s not necessarily easy to access it and get the predictive overview you want from it. You want to be able to take that demand occurred and filter it. You don't want that covid pandemic related demand to affect what your future demand is going to be.

If you’re a business that is looking to make sure that you've got a system that has the ability to go ahead and filter that type of information you want to have it available so you can plan in case it happens again. But when it's not happening, we have the ability or we need to have the ability to filter it out, because we want to get to that state of normalcy.

Are there new or emerging trends in buyer behavior and in supply chain planning that we can expect to hear more about in 2021 and possibly in 2022?

It’s very clear from where we’re standing now that times are going to change. We have to have the ability to lock onto those new trends that will emerge from this. The industry is - and has been for a while - seeing an increasing move towards artificial intelligence (AI), specifically with neural net forecasting. Now, neural net forecasting is a great topic to drop at a cocktail party because everyone thinks you’re really smart. But what we’re really talking about when we mention AI here as a trend is the ability to take complex, linear relationships and understand the cause and effect. In the coming years, it’s going to be more and more important to be able to identify trends within trends.

For example, the purchase of one particular item drives the purchase of another one, which drives another one. Once businesses are able to leverage technology to understand those relationships, they can make fast and impactful decisions. That’s where neural net forecasting, which Blue Ridge is working on, is going to help companies, whether in food and beverage or online retail.

When considering NetSuite or Blueridge as a solution for your business, is there one that should be implemented before the other?

It's really going to be a situational decision. There are advantages to either. Back in the day, an ERP was a must-have and a solution like blue ridge was a nice to have. Today, we have more competitive environments because the market is changing.

We're more focused on things like the bullwhip effect, you know, the kind of things we're talking about today are becoming more complex, more growth-driven. A supply chain solution like blue ridge has become a must-have for many, many businesses that need to streamline.

It depends on the situation, if you have a modern ERP solution that you can go live within a period of six to nine months, you could also implement Blue Ridge simultaneously. This requires sitting down with your team and setting priorities based on what your needs are. What makes the most sense for your business?

Blue Ridge has customers who have actually paid for the ERP implementation through the use of Blue Ridge. But keep in mind, if you don't have an ERP solution or a strong back-office, it's probably a better thing to get that installed first because Blue Ridge is dependent on the item master and the source master information. Good information gets good information, bad information....well, that’s where you have to consider if you have a good back-office. Are you organized enough to really take advantage of the next step?

Whether you're already using an ERP or shopping for one, trying to optimize your processes and supply chain management or have any questions, you can contact Blue Ridge or GURUS Solutions either way. Our companies collaborate closely to create impactful cloud solutions that cater to Manufacturing, Wholesale Distribution, Retail, eCommerce, Food and Beverage and more.