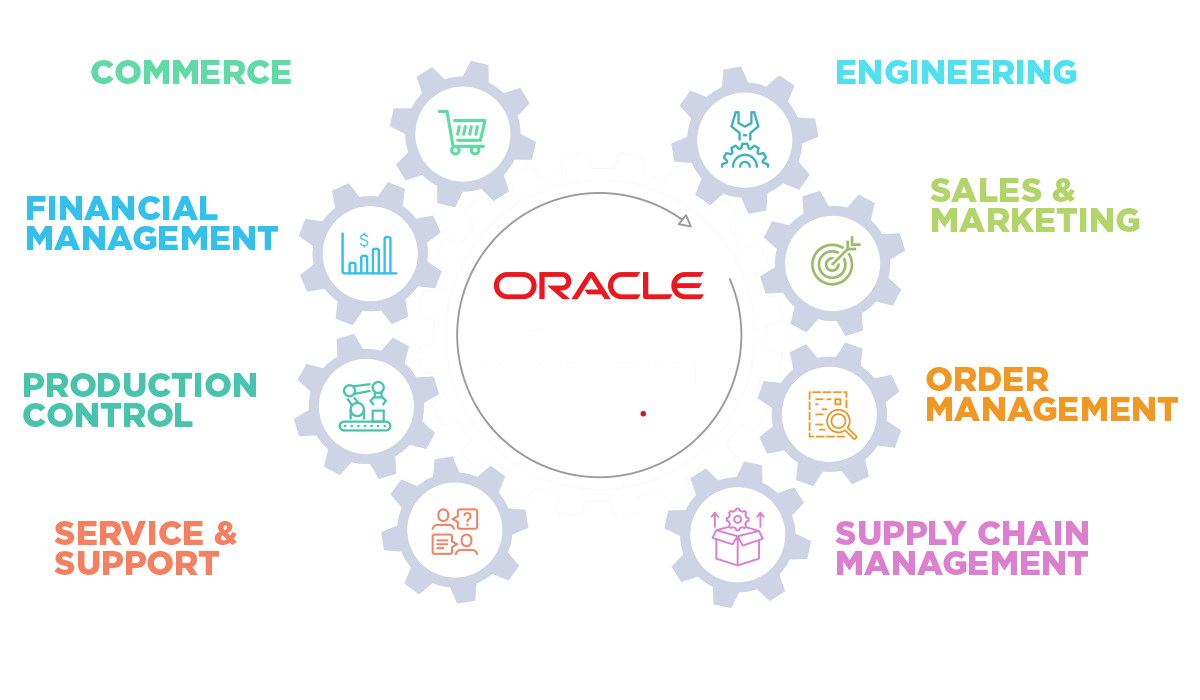

NetSuite ERP software for Manufacturing (MRP) gives you real-time visibility across your entire organization, enabling:

- Next Level Supply Chain Management - Streamline Your Day to Day Operations and Simplify Your Resource Planning

- Improved Production Control - Leverage Automation for Better Work Order Management & Scheduling & Ensure Product Quality

- Financial Management - Streamline Your Finances for Everything from Intercompany Accounting to Costing, Managing Payments, and More

Top manufacturers are making the switch to the cloud, find out how you can too. Contact an expert for information on implementation, customization, training, support, and more!

Talk to a NetSuite Manufacturing Implementation Specialist

Cloud-Based ERP for Manufacturing

Transform your manufacturing processes and supply chain with a cloud-based erp for manufacturing and discover the simplicity of your operations.

How to Increase Profits with NetSuite ERP

NetSuite ERP for manufacturing is the ideal solution for companies looking to keep a limit on cost all while scaling their business without a hitch.

Manufacturing Workflow with NetSuite

NetSuite ERP ensures successful and advanced manufacturing operations from beginning to end with a complete manufacturing workflow system.

NetSuite for Manufacturing

How NetSuite ERP for Manufacturing Can Help Your Business

- A COMPLETE MANUFACTURING SOLUTION

NetSuite's software suite is the best choice for manufacturers wanting a complete business solution. Its comprehensive functionality, which includes ERP, CRM, HCM and eCommerce capabilities, provides manufacturers with the software needed to run a modern business. - AGILITY

React swiftly to opportunities and challenges—NetSuite replaces unwieldy and complex processes with one software suite that pre-empts delays and errors that impact costs. - PRODUCTIVITY

Achieve more with your existing resources—NetSuite converts silos of suppliers and consumers into synergistic partnerships that maximize profitability and loyalty. - TRANSPARENCY

Stay informed about every aspect of your business—NetSuite features a unified architecture that provides actionable insights about every aspect of your operation, anytime, anywhere.

Hear Our Manufacturing Clients Explain Why They Chose NetSuite ERP & GURUS

Your Industry

Every business faces unique opportunities and challenges. Our expertise, acquired from working with thousands of manufacturers, enables us to fulfill your specific requirements. Our software suite addresses a wide variety of production methods.

Make to Stock / Forecast

You purchase or manufacture products to meet forecasts and put them into stock.

Assemble to Order

You assemble products after receiving an order (and often make sub-components to stock / forecast).

Make to Order

You manufacture products after receiving an order (and tracking labor and burden costs are especially important).

Process-driven

You use formulas or recipes, instead of BOMs, and often manufacture in batches.

Configure to Order

Your products have some variability and features / options are selected when an order is received.

Field Repair and Service

You provide a service that repairs and / or enhances products made by a third-party.

Engineer to Order

You design and manufacture large / complex products based on customer specifications.

Project-driven

You use projects to manage the process of building large / complex products.

Design, Supply and Install

Your business mostly revolves around supplying and installing products (and carefully managing that process is vital).